New polysiloxanes-based ceramic membranes for emulsion separation/creation and membrane distillation

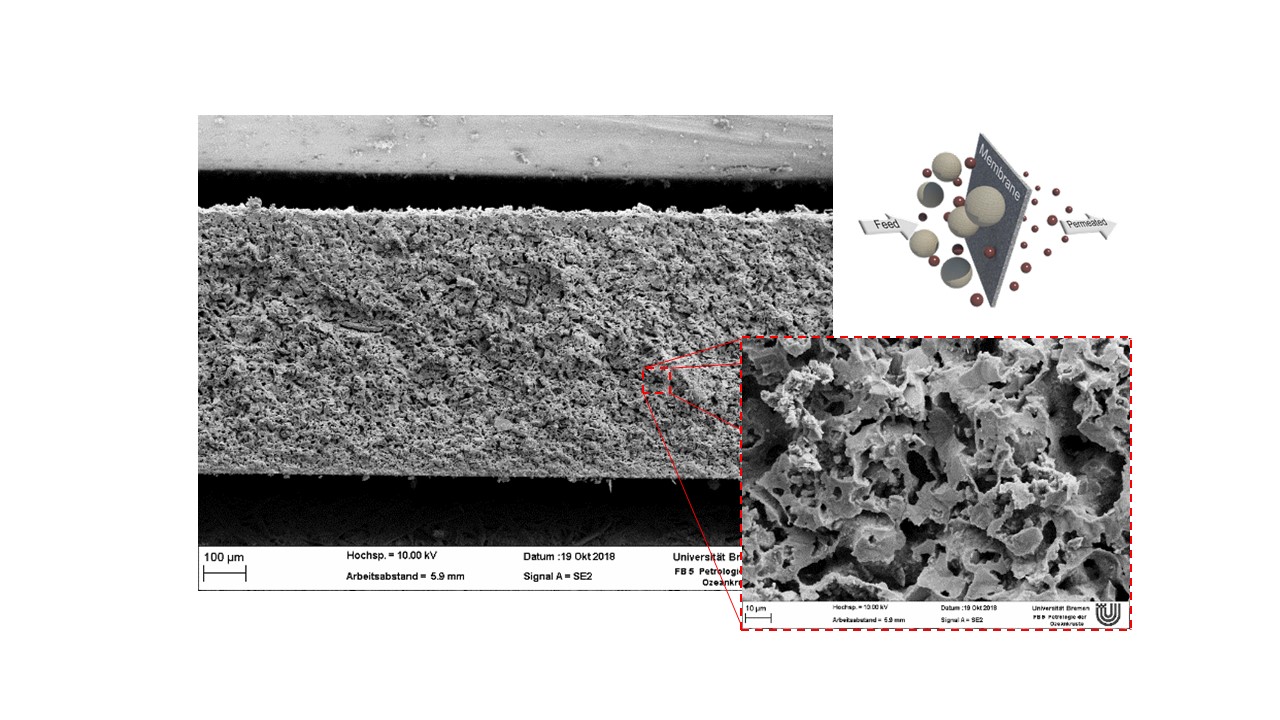

Porous membranes with well-defined pore sizes have been drawing increasing attention in recent years due to their numerous potential applications, as an alternative to conventional energetically intensive separation techniques, such as distillation and evaporation. The membrane technology present a selective and efficient transport of specific components, providing a reliable option for a sustainable industrial growth. In this project, polymer derived ceramic (PDC) precursors will be used to develop a porous membrane with tailorable characteristics (pore size, pore size distribution, hydrophilic/hydrophobic character) using different shaping methods (e.g. tape casting), aiming future applications in oil/water emulsions separation/creation and membrane distillation (MD) processes. The membrane structure, especially pore size and its distribution will be evaluated in terms of the choice of the precursor, the solvent, the nonsolvent and process parameters. The mechanical stability of the membranes should be improved by incorporating filler particles. Finally, a thermal process under controlled atmosphere (pyrolysis) would impart ceramic characteristics to the produced membrane, such as high mechanical resistance, high chemical stability and thus longer lifespan. The influence of pyrolysis temperatures on the hydrophilic/hydrophobic character of the membranes will be assessed in the range 600 – 1000 °C. These structures will be initially tested in permeability and emulsification experiments. Further, the development of effective membranes for MD experiments will also be investigated.