Transport, separation and mixing of complex multiphase fluids in pores and porous membranes with varying surface activities

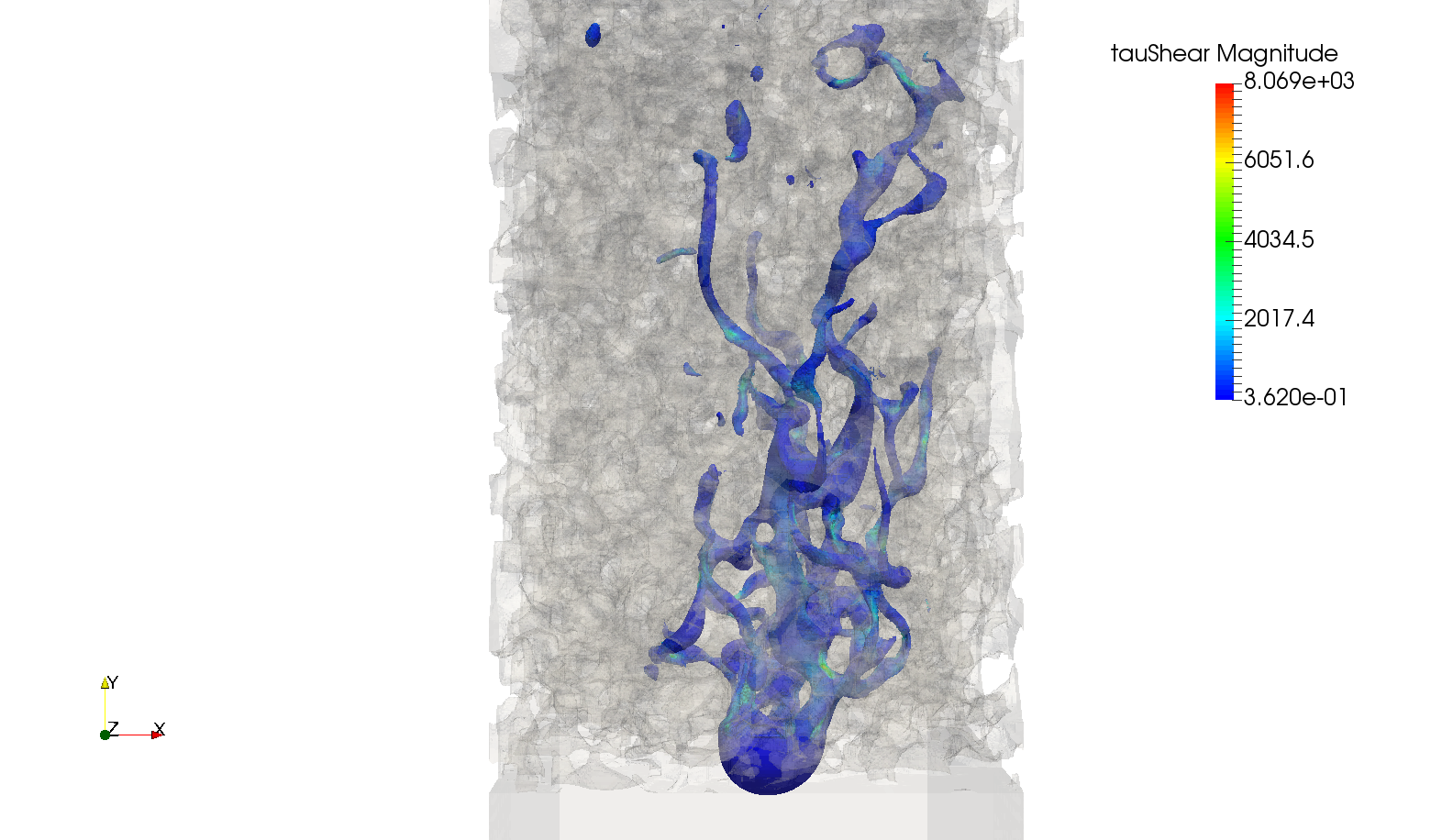

Emulsions are used for special liquid formulations. For instance, multiple emulsions like w-o-w systems (water in oil in water) are utilized in pharmaceutics, medical and food technology. The inner water phase is encapsulated and can be applied for a controlled release of e.g. drugs. Pickering emulsions are formulated by dispersing colloidal particles at fluidic interphases and thereby encapsulate a fluid that may be released by coalescence of the inner phase or by permeation through the outer membrane. An established method for producing and formulating emulsions and encapsulated liquids is performed by dispersion of liquid/liquid mixtures in porous membranes. Here especially shear sensitive liquids may be formulated. This premix emulsification process in porous ceramic membranes offers flexibility in droplet size generation, mechanic stabilization of membranes and complex fluid formulations. In the project, micro encapsulation and multiphase transport, mixing and dispersion in porous membrane structures are to be analyzed by means of experiments as well as modeling and simulation. Efficient formulation methods for complex fluid-fluid dispersions and encapsulations of dispersed systems will be derived in this way. In this third phase of the premix-emulsification project, surface functionalization and activity modification of membranes as well as of particles to be encapsulated will be investigated. With respect to the surface functionalization of the porous membrane, liquid/liquid mixtures can also be separated (liquid filtration). In combination with (NMR cooperation Dreher) experiments liquid retention and distribution in membrane filters may be analysed. Model structures for simulation are to be derived e.g. from µCt scans (cooperation Odenbach). Liquid surface rheology properties in terms of surface active components (like proteins, surfactants, polymers and particles) are mainly responsible for changes in the liquid topology like fragmentation and coalescence and the interaction of the liquid with the bounding membrane walls. Static and dynamic absorbance investigations contribute to model derivation. These properties have a certain impact during premix emulsification and need to be adequately addressed. Numerical modeling of these fluids behavior is still a challenge (cooperation simulation in Mimenima).

Cooperations within Mimenima:

AG Dreyer: Modeling and Simulation two-phase flow (P10/03)

AG Odenbach: µCT-characterization of porous structures and liquid distribution in membranes (P05/03)

AG Dreher: NMR analysis of two-phase flow and phase distribution (P04/03)

AG Thöming: Characterization of transport in porous media (exp and num) (P07/03)

AG Wilhelm: Production of tailored microstructures (02/03, 18/02)

AG Maas: Surface rheology and wall interactions (P01/03)

AG Wriedt/Mädler: Transport models and simulation (P09/03)

AG Rezwan: Computer analysis of porous structures (10/03)

Fig. 1: Dispersion of a 500 µm oil droplet in a porous membrane (from Ct-scan) with local interfacial stress distribution

Contact:

Fritsching,

Thöming