Monolithic catalysts of graded porosity

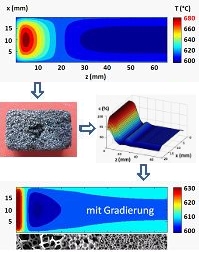

Catalytically active foam structures and monolithic catalyst supports may offer advantageous mass transport properties and simultaneously reduced pressure drop compared to conventional fixed beds. These advantages are especially attractive for exothermic reactions, such as Fischer-Tropsch synthesis and Autothermic Steam Reforming (ATR) of biogas, two interesting candidates for producing fuels based on renewable energy ressources. However, using catalysts of graded porosity under such exothermic gaseous phase reactions is connected to two challenges. First, large temperature gradients arise that can destruct the catalyst structures in hot temperature zones. This occurred during our tests with ceramic monoliths. Second, the structure of the catalyst support determines, together with the catalyst itself, both main parameters of the reaction, i. e. conversion and selectivity. Preliminary studies have been made concerning simulation of ATR-reactions in foams (Hüppmeier et al. 2008) and preparation of graded porous structures and their efficiency in an ATR-reactor (Hüppmeier et al. 2010). Further, the influence of rarefaction and thereby of pore radius on mass transport was demonstrated by analytical modeling (Veltzke and Thöming 2012). In addition, the effect of a graded distribution of the porosity has been calculated which resulted in an almost isothermic ATR-reaction (see figure). This method should further be developed in this project addressing longitudinally graded pore structures of the catalyst supports. Our working hypothesis is that heat transport as well as mass transport can be influenced locally by spacial distribution of pore properties. This shall be proved by means of experiment and simulation.

Reference list of own results:

J. Hüppmeier, M. Baune, J. Thöming (2008) Interactions between reaction kinetics in ATR-reactors and transport mechanisms in functional ceramic membranes: A simulation approach. Chem. Eng. J. 142 (2008) 225-238

J. Hüppmeier, S. Barg, M. Baune, D. Koch, G. Grathwohl, J. Thöming. Oxygen feed membranes in autothermal steam-reformers - a robust temperature control. Fuel 89 (2010) 1257-1264.

T. Veltzke, J. Thöming. An analytically predicting model for moderately rarefied gas flow. J. Fluid Mech. (2012) accepted