New polysiloxanes-based electrode materials for Microbial Fuel Cells (MFCs)

Deep

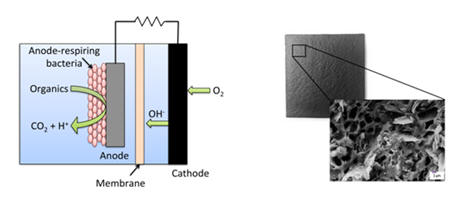

Two major problems that human beings are now facing are that

of environmental pollution and the energy crisis. MFC represents a technology

that has the potential to address simultaneously both these major problems, as

energy is generated in the form of direct electricity for onsite use during

treatment of wastewaters. Although there has been marked improvement in the

performance of MFC through research, large scale practical application of MFCs

is yet to be achieved. The main constraints for practical application of MFCs

are the high fabrication cost and low energy conversion efficiency.

Hence, to reduce the capital cost of this device, it is necessary to develop

and design economic and cheaper electrode materials which show a comparable

or even better performance. The properties required for the electrodes materials

are different. Anode should be a bio-compatible, conductive, non-reactive material

offering a very high surface area, and should be permeable for the substrate to

avoid kinetic limitations. Similarly cathode material should have catalytic

activity for oxygen reduction apart from higher surface area. Due to an

outstanding collection of properties new electrode materials based on polymer

derived materials are a promising class of new materials.

This project will focus on the development of new electron conducting anode

materials derived from polysiloxanes with high chemical stability, highly

conductive and adjusted porosity and surface characteristics.

Of main interest is optimize the interaction between the biofilm and anode

surface and with this achieve an increased overall performance of a MFC.

Additionally a cathodic support structure with adjusted porosity and surface

structure should be synthesis and tested. The first set of results will be done

by using this inorganic-organic polymer in combination with high conductivity

carbon fillers as starting material that will allow the generation of electron

conducting hybrid materials, which possess a higher chemical stability than

pure carbon materials, high specific surface areas and adjustable surface

characteristics in terms of hydrophilicity or hydrophobicity.

Different compositions (in terms of fillers), dimensions and pyrolysis conditions

should be tested and characterized. Moreover, a fuel cell set-up should be

established that allows measurements with a model solution of bacteria.

Based upon the observations from these experiments, another aim is to address

the scaling up issues of MFC for industrial application. Additionally, cooperation

with Indian partners will provide testing results gain for the new electrodes

materials with MFCs which are operated in a wastewater environment.