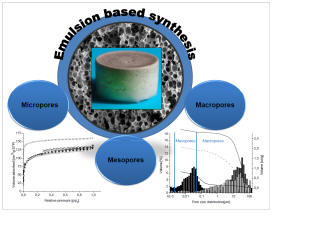

Polymer derived ceramics with controllable pore size distribution and adjustable surface characteristics synthesized by emulsion processes

The aim of this research project is the emulsion based synthesis of hierarchical monolithic ceramers with a high content of organic groups. The surface characteristics should be controlled in a broad range in terms of hydrophobicity/hydrophilicity for potential application like gas separation by incorporation of functional organic groups. Materials for gas separation processes should show a trimodal pore size distribution. Macro and mesopores allow effective mass transport processes and micropores generate high specific surface areas for better adsorption capacities. The surface characteristics should be controlled in a broad range in terms of hydrophobicity/hydrophilicity, so that an adjustment for specific systems is possible. Based on the literature known works on Si(HIPE)s (HIPE = High Internal Phase Emulsion) a synthesis pathway will be developed which allows the incorporation of organic groups into monolithic emulsion based ceramers in a one-pot-synthesis The skeletal structure of these materials will be formed by methyl and methylphenyl polysiloxanes (MK and H44) which will be functionalized additionally with amino groups by using (3 aminopropyl)triethoxysilane. In addition, the amine groups should be used for incorporation of metal ions into the ceramers, subsequently or in-situ in order to enhance sorption capacities for specific gases. Adjustment of pore size distribution for effective mass transport processes for gas separations processes should be developed by using various oil/water ratios and by the choice of different types of emulsions. An adjustment for the adsorption of different gases and solvents with different polarities should be possible using different precursor with different organic groups. A homogenous distribution of metal nanoparticles in the emulsion-based hybrid monolithic ceramers can enhance the adsorption of different gases. .